ERC Consolidator Grant #772873

Prof. Alejandro A. Franco

ERC Consolidator Grant #772873

Prof. Alejandro A. Franco

Work Package (WP) 1 consists at developing, integrating and demonstrating the modeling tools allowing to simulating the different steps along the fabrication process of lithium ion battery cells.

Work Package (WP) 1 consists at developing, integrating and demonstrating the modeling tools allowing to simulating the different steps along the fabrication process of lithium ion battery cells.

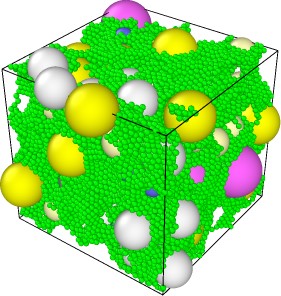

Coarse-Grained Molecular Dynamics (CGMD) and Discrete Element Method techniques are used to predict self-organization of the slurries and of the electrode mesostructure during the solvent evaporation and calendering steps, as a function of the chemistry of the materials and fabrication parameters (slurry composition, particle sizes distribution, type of solvent used, drying temperature and time, etc.). Experimental data produced in WP 2 together with machine learning algorithms are adopted in order to parameterize the Force Fields describing the interactions between the materials in the slurry, in the coating and calendering steps.

These simulation tools aim to be universal in regards to the materials chemistry, and are first tested for NMC; LiFePO4 and graphite, silicon and Li-rich materials for the active materials. Multiple binders are studied (e.g. PVDF), carbon additives (e.g. Super P®), slurry solvents (both aqueous and non aqueuous) and dispersants.

The predicted electrode mesostructures are analysed in terms of descriptors such as porosity, active material coverage by binder, aggregate size distributions. An in house Virtual Reality software is also used to visualise the predicted electrodes. A mathematical smoothing procedure is then applied on the resulting mesostructures to generate electrodes representations usable in:

a Lattice Boltzmann model simulating the electrolyte invasion dynamics in the porous electrode;

the performance cell model developed in WP 3.

Work Package (WP) 2 consists in the fabrication of slurries, electrodes and cells following the materials and fabrication protocol specifications specified in WP1. The electrodes and cells are fabricated using the prototyping facilities already available at the Laboratoire Réactivité et Chimie des Solides to mimic industrial processing conditions. Fabricated components and cells will also include the optimized electrode architectures arising from the cell performance simulations carried out in WP3.

Work Package (WP) 2 consists in the fabrication of slurries, electrodes and cells following the materials and fabrication protocol specifications specified in WP1. The electrodes and cells are fabricated using the prototyping facilities already available at the Laboratoire Réactivité et Chimie des Solides to mimic industrial processing conditions. Fabricated components and cells will also include the optimized electrode architectures arising from the cell performance simulations carried out in WP3.

In order to validate the CGMD models developed in WP1, slurries are characterized in regard to their properties (e.g. viscosity), whereas the mesostructural characterization of the electrodes is carried out by different complementary techniques, including gas adsorption porosimetry (porosity and tortuosity), X-ray tomography and 3D FIB/SEM. Coatings electrical conductivities and mechanical properties are also characterized.

Work Package (WP) 3 is devoted to completing the workflow developed in WP1 by developing a novel computational tool for the prediction of the influence of the calculated electrode mesostructures in WP1 on the battery cell performance. The cell model incorporates the smoothed electrode mesostructures arising from WP1 and the relevant physicochemistry as effective parameters. The model describes with three-dimensional resolution the mechanisms taking place in the sandwiched negative electrode/separator/positive electrode system, as a set of coupled partial differential equations (PDE) solved through the finite volume/element method: electrochemistry, ion transport, electronic transport, porosity changes due to active material volume expansion when relevant (case of silicon) and associated degradation due to mechanical stressors. From the coupling of this model to an optimization algorithm with the energy density as merit function, analysis of simulated charge/discharge curves in terms of relevant descriptors (e.g. over potential, maximum specific capacity) permits discovering optimal and innovative electrode architectures (e.g. specific porosity gradient along the electrode thickness) that are proposed to WP2 for fabrication with the guide of the WP1 models for the most convenient manufacturing approaches to use.

The integrative multiscale platform arising from the combination of the fabrication models in WP1 with the performance model in WP3 will be implemented in this webpage (see section Computational Portal) for open access online battery performance simulations. The online platform will operate with a pre-calculated repository of electrode mesostructural databases generated in the project but it will also allow the users to enrich it with their own databases.

Finally, this WP addresses the evaluation of the uncertainties propagation within the computational workflow: several Uncertainty Quantification approaches are investigated to analyse uncertainties and errors propagations, and control strategies are defined with the support of the feedback between simulations (WP1, WP3) and experiments (WP2, WP4).

Work Package (WP) 4 provides validation data for the cell model developed in WP3. Fabricated electrodes, including the ones with the most promising architectures from the generated computational data outputs, are experimentally tested at the lab scale from an electrochemical viewpoint (e.g. charge/discharge curves, GITT and EIS) through advanced characterization tools already available in the Laboratoire de Réactivité et Chimie des Solides (e.g. potentiostat coupled to in operando XRD).